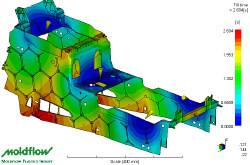

Complex Problems Solved using Moldflow CAE Simulation!

The plastics injection molding process is integral to many of today’s mainstream manufacturing processes. Industries such as telecommunications, consumer electronics, medical devices, computers and automotive all have large, constantly increasing demands for injection molded plastic parts. There are thousands of different grades of commercial of plastics materials with widely varying processing characteristics and complex part and mold designs are constantly pushing the limits of the process.

The production of injection molded parts is a complex process where, without the right combination of material, part and mold design and processing parameters, a multitude of manufacturing defects can occur, thus incurring high costs.

Plastic Flow Simulation. (moldflow) Computer aided engineering (CAE) tools are used to simulate the manufacture of plastic parts and the results help our engineers correct defects on the final design, before mould tool manufacture is completed.

The above factors bring a level of complexity to injection molding that makes it necessary to use Moldflow CAE tools to predict and solve potential problems before they occur. Additionally, the cost of tooling for injection molds can be very high and subsequent rework increases these already high costs. All these factors combine to make injection molding an ideal application for CAE simulation using Moldflow. Imtech Design has been providing answers to complex moulding problems using Moldflow software for 21 years and able to supply quick practical solutions to keep your plans on track and within budget.